新闻资讯

15

2025

-

04

展会预告丨CIMT2025中国国际机床展 4.21-26英络克展位W3-B412诚挚邀约

Author:

第十九届中国国际机床展览会(CIMT2025)

THE 19TH CHINA INTERNATIONAL MACHINE TOOL SHOW

科技峰会 启迎未来

四月春风暖,又逢盛会

2025CIMT第十九届中国国际机床展览会

如约而至,盛装起航

展会聚焦高精、高效、数字、智能、绿色发展

欢迎您莅临展会现场参观指导

4月21—26日

在北京中国国际展览中心(顺义馆)

展位号:W3-B412

英络克工具将为您提供更精准的服务!

Part.01 关于展会

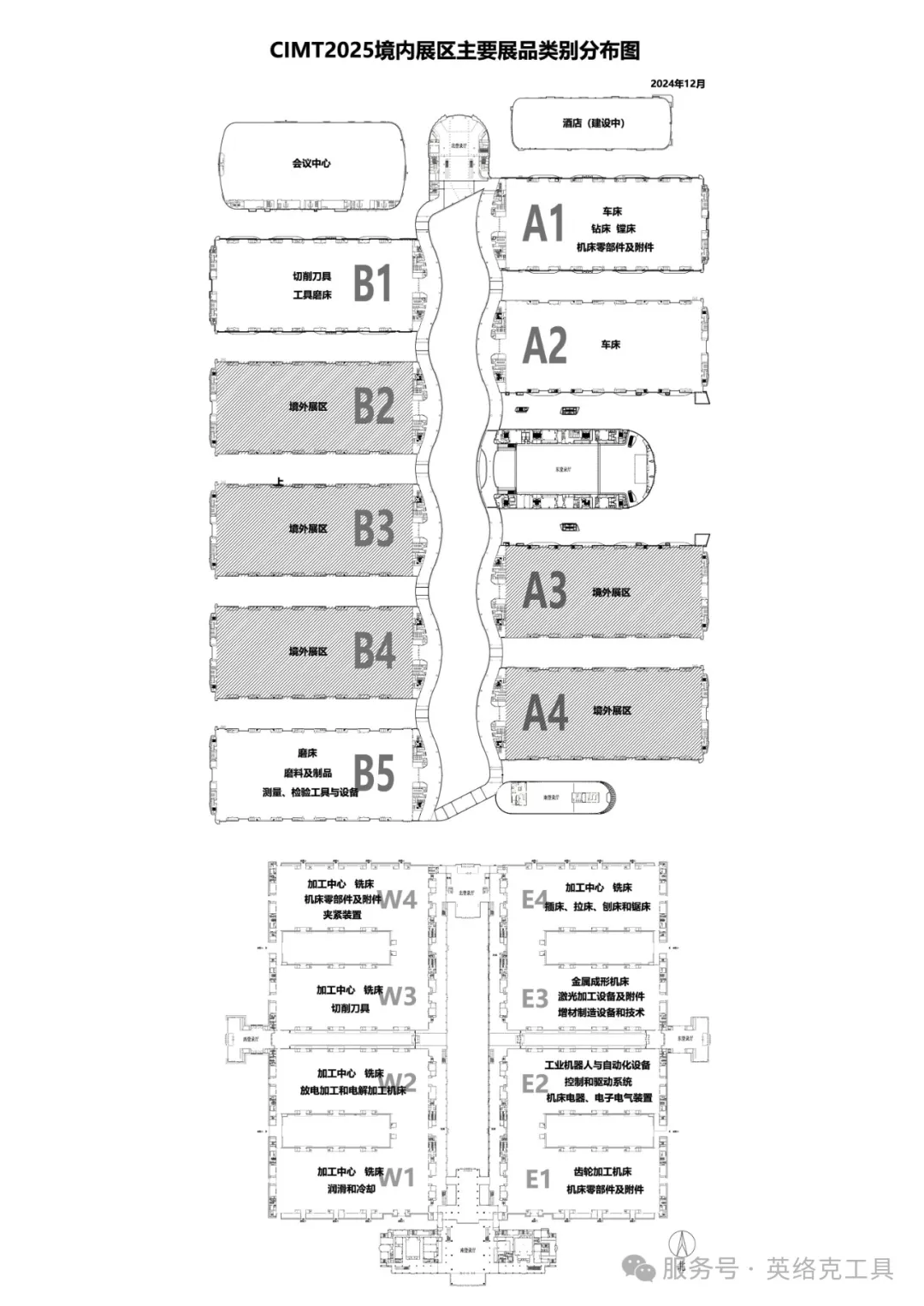

第十九届中国国际机床展览会(CIMT2025)将于2025年4月21至26日在北京首都国际会展中心(新国展二期)和中国国际展览中心(顺义馆)举办,总展出面积达31万平方米,中国国际机床展览会(CIMT)即将迎来其发展史上具有里程碑意义的一届盛会。

CIMT2025顺应时代发展,整装扩容,为全球机床工具制造商提供绝佳的展示平台,各式先进的机床工具精品将在这个大舞台上同台竞技,全球机床工具业界的最新成果将在这里集中展示,全球机床工具业界的未来技术发展趋势将在这里充分交融。

Part.02 公司介绍

台州市英络克工具有限公司

TAIZHOU YINLK TOOLS CO.,LTD.

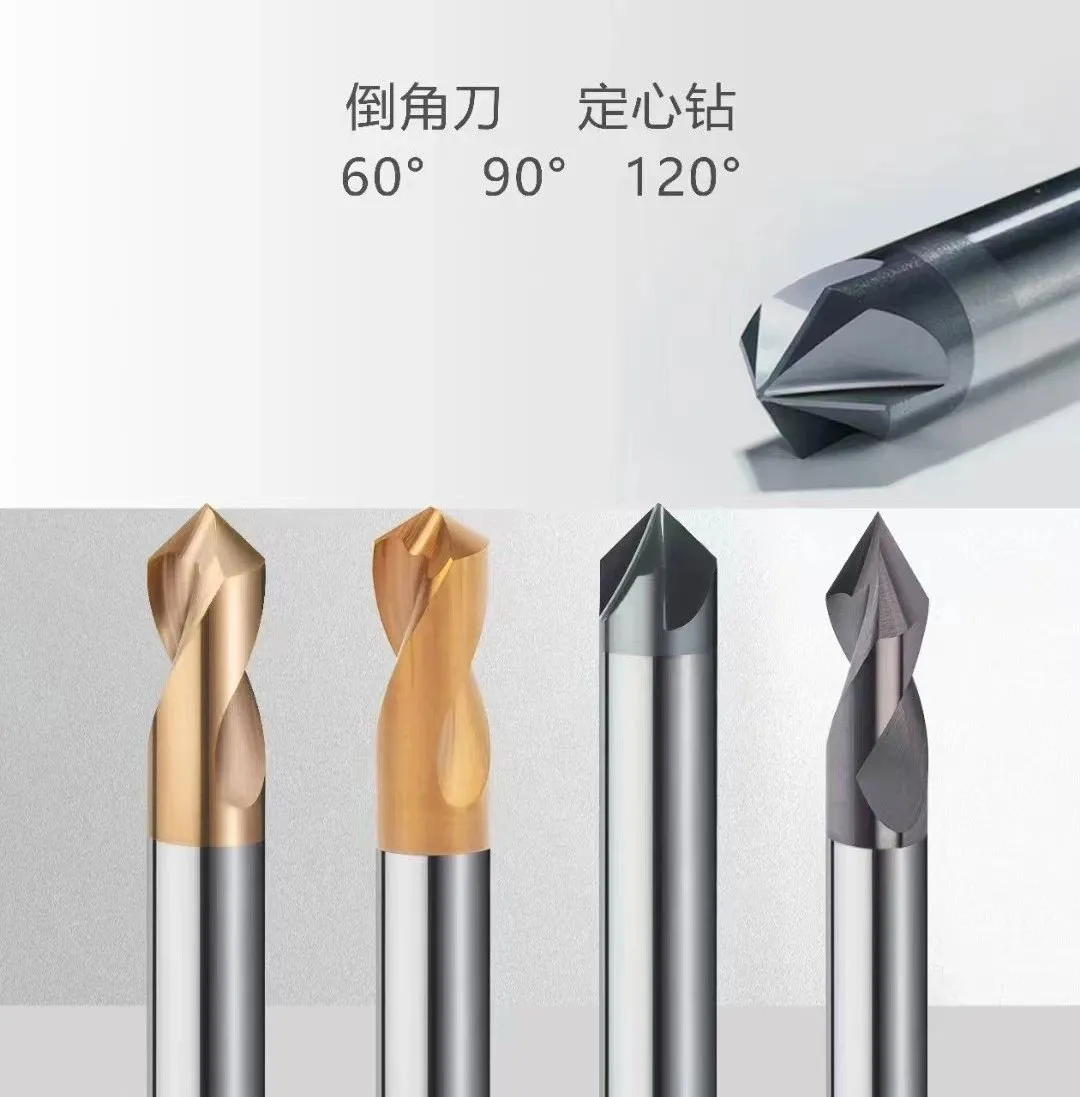

台州市英络克工具有限公司是台州一家拥有世界先进的德国瓦尔特五轴联动工具磨床和HELICHECK PLUS精密检测等设备的企业,公司专业研制生产和修磨硬质合金(钨钢)立铣刀、钻头、球刀、R刀、圆鼻刀、燕尾槽、铰刀、镗刀、阶梯钻、内冷钻、中心钻、成型刀、螺纹铣刀、轮廓刀等标准和非标准的回转类精密切削刀具。为模具制造、汽车零部件加工、航空航天工业的先进切削和孔加工技术提供成套的解决方案。

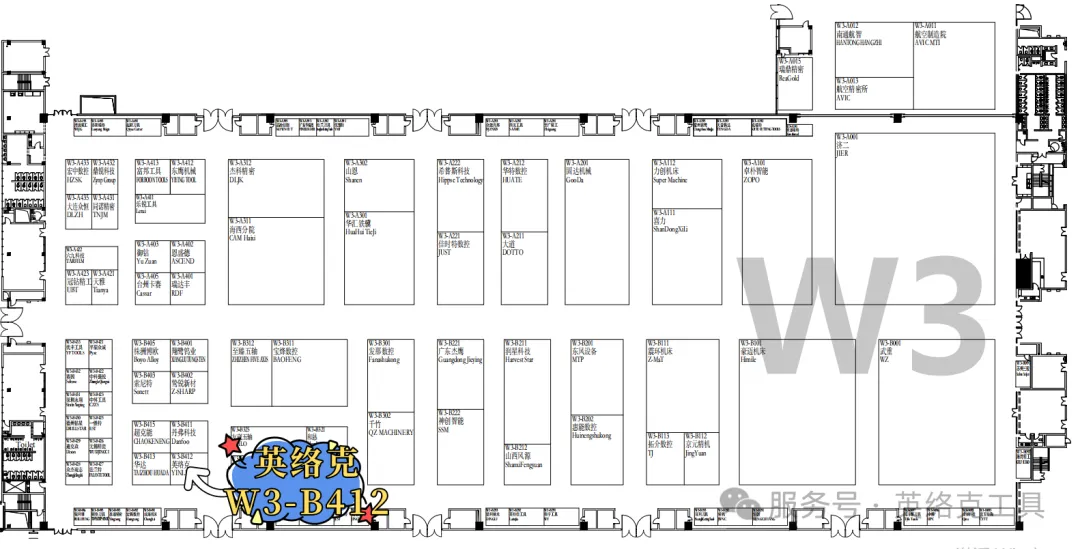

展会位置

中国国际展览中心顺义馆W3馆

北京市顺义区裕丰路88号

中国国际展览中心(顺义馆)

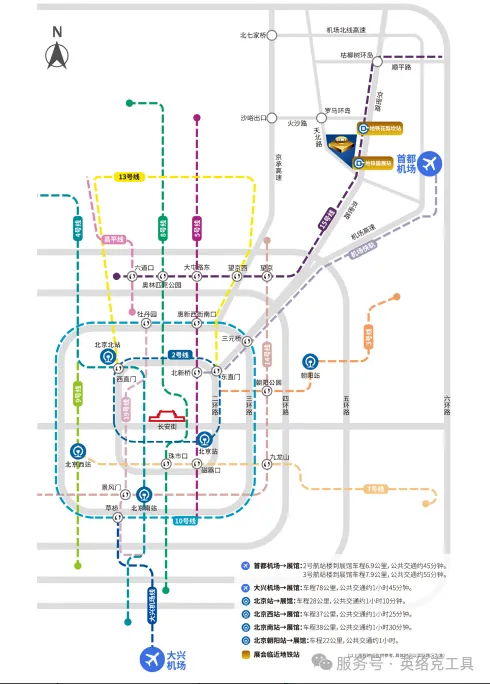

展馆交通指南

展馆名称:中国国际展览中心(顺义馆)

展馆地点:北京市顺义区天竺地区裕翔路88号

一、公共交通

经地铁:乘坐地铁15号线到“国展”站下车即到。地铁15号线可与地铁5号线、8号线、13号线、14号线实现换乘。

公交车:请通过手机地图导航软件搜索:中国国际展览中心(顺义馆)顺义区裕翔路88号,可选择916/915/980路公交车到地铁国展公交站下车,或者您也可以实时导航选择最优线路乘车。

二、自驾车

请通过手机地图导航软件搜索:中国国际展览中心(顺义馆)北京市顺义区天竺地区裕翔路88号,展会主办单位将安排指定公共停车场,并在展馆周围道路设立指示牌,抵达后根据指示前往停车场,转乘摆渡车前往展馆。

相关推荐

暂无数据